Plywood Cutlist Optimizer Free Cut List

Works with plywood, MDF, glass, plastic, metal, fabric or any other material. It reduces waste and will save you money. SmartCut calculates efficient cut list diagrams for your sheet and linear materials. Free cut list optimizer for iOS, iPhone & Android.

Plywood Cutlist Optimizer Software Lets You

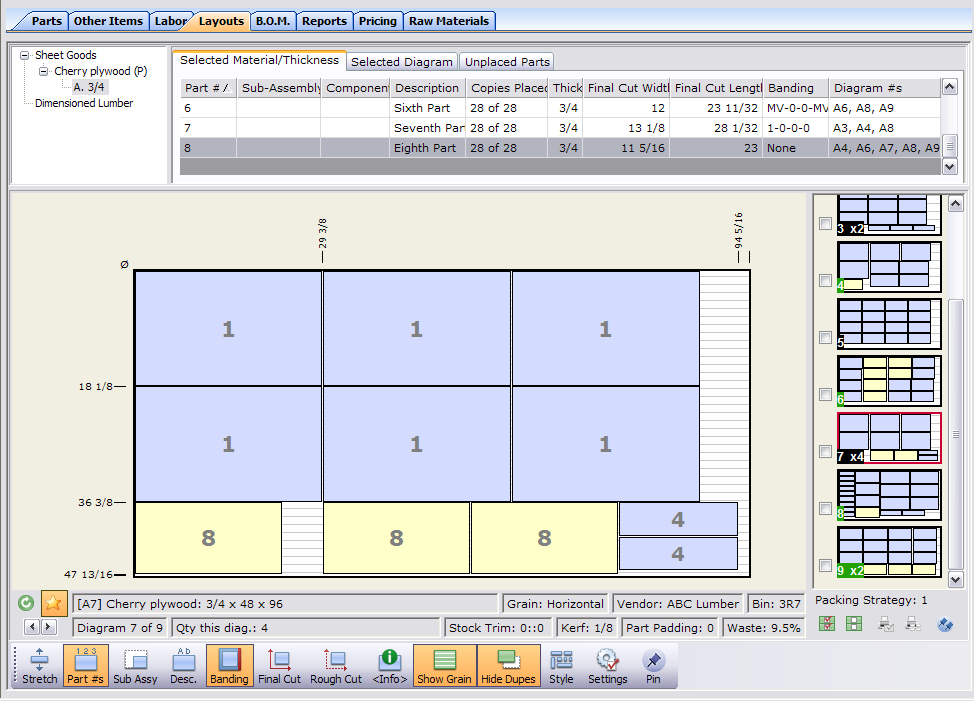

It generates optimized cutting patterns based on the available stock sheets by nesting the required parts.I found Cutlist Optimizer a while ago whilst designing my new workshop (also in Fusion 360 – trust me Fusion is not the best tool for designing buildings even wooden ones!).From the developer: CutList Plus woodworking software lets you quickly generate cutting diagrams that make the most efficient use of your plywood and lumber.While looking at workbench designs for my soon-to-be-built space I stumbled on Suso’s Modular Workbench over at PS Woodworking ( well worth a visit – Suso has some really cool woodworking projects for the workshop) which I really liked but wanted to “fiddle with”, so I recreated it in Fusion 360. Generates optimized cutting layouts for sheet materials, including plywood, lumber, glass, metal, granite, fabric, and any other material in rectangular sheets. This article grew out of my experiences with BOM’s, cut lists, and sheet fitting solutions for me to use as a “Hobby Woodworker”.CutList Optimizer is an application targeted for panel cutting optimization. Cutlist plus cutting diagram software: sheet layout optimizer for plywood.Those of you who read the PDO Community Fusion 360 Q & A may have spotted BOM’s – Am I missing something? The original question triggering my foray into BOMs and Panel Cutting. A professional cutlist optimizer to calculate efficient layouts on linear. You add up the different board cuts and that is the total amount of.

Enabling the Selected only option when creating the BOM allows you to highlight the items you wish to include in the export but if you later change the visibility in the browser you may inadvertently change the items included.I found it simpler to exclude specific components by starting their names with an underscore ( _component) and enabling the Exclude “_” option when creating the BOM. Even here the “wide leg” pairs were created by copying and then rotating the components rather than mirroring. Using “Copy” results in a single item in the BOM with the quantity incremented by 1, “Mirror” or “Copy New” both produce multiple items in the BOM, each with a quantity of 1, the same dimensions and different labels.Looking at the current design there are a couple of instances where I had to “Copy New” to allow the creation of drawer slides on the front face. Use “Copy” rather than “Mirror” or “Copy New” when duplicating components. Component names are important, they become the panel labels in the cut list so meaningful names are recommended. Getting the BOM out of Fusion…Designing an item with a view to BOM production has a few “gotchas” of its own as I discovered to my cost – it took a number of iterations of both the Fusion design and BOM export to get the result I wanted.Download the Fusion file if you wish to follow along…

You’re heading in the right direction if the Delta figures are close to those in the exported BoM CSV.Obviously, knowing about this “feature” and being aware that it may cause issues with a design component is not a solution. Looking at an exported CSV file we see “Part name, Quantity, Width, Length and Height” in whatever unit the design was created in.The data is as expected if the components have a horizontal or vertical orientation, but what about components created at an angle? This example illustrates the problem.The item is actually 141.421mm long and 30mm high but Fusion 360 doesn’t interpret this as a part at an angle, it just returns 100 mm x 100 mm, the height and width of the bounding box that contains the item.Whilst this interpretation is “correct” it gets more “interesting” when dealing with long structural timber (a 4×2, diagonal brace for example) which the BOM export reports as something wildly different from the actual component.If you think you’ve got a problem double-check the component in Fusion 360 using the INSPECT>Measure tool with the XYZDelta option turned on. When is a BOM not a BOM?Working on another project recently reminded me why I was initially looking at OpenBOM as a possible solution for my Bill of Materials and Cut list needs.Fusion 360’s BOM export appears a little “odd” on occasion. Making modifications to incorporate these items results in the need of “Copy New” for some components to stop the changes spreading across all the matching panels, which increases the complexity of the panel list with multiple components with identical dimensions and different labels. It’s missing items such as T-track and dog holes on the front face.

0 kommentar(er)

0 kommentar(er)